|

Ships |

||||||

|

Miss England II by Replicast |

||||||

|

by Peter Radcliffe © 2006 Modeler Site |

||||||

|

Legal Notice No material from Modeler Site any Web site owned, operated, licensed, or controlled by Damian Covalski may be copied, reproduced, republished, uploaded, posted, transmitted, or distributed in any way, except that you may download one copy of the materials on any single computer for your personal, non-commercial home use only, provided you keep intact all copyright and other proprietary notices. Modification of the materials or use of the materials for any other purpose is a violation of Damian Covalski's copyright and other proprietary rights. Read More here > Legal notice In 1928 The American Gar Wood set the first Official Water Speed Record of 92.8 mph. In his Boat Miss America VII. In 1929 Sir Henry Segrave the holder of the Land Speed Record at 230 mph commissioned Fred Cooper to design "Miss England II" to take the record. She was a single step hydroplane of 38 foot length powered by two supercharged Rolls Royce R engines as used in the Schneider Trophy Supermarine S6. The engines powered a single screw and this was thought in part to cause stability problems that its twin screw successor would not suffer.

In May 1930 on Lake Windermere she set a new two way record of 98.76 mph. The run however ended in tragedy as after setting the time she hit a submerged log, swerved and cartwheeled her crew into the water. Segrave and Halliwell were killed but engineer Wilcocks survived. It is this that the model depicts.

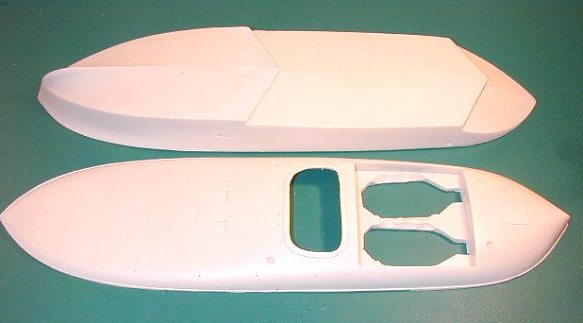

The kit This kit produced by Fred Harris of Replicast is typical of the products from some of the very small manufacturers. The kit is entirely with exception of decals produced in house. The result is that the standard of casting is not up to the standard produced today by the specialist companies like CMA Moldform or the larger manufacturers such as Provence Moulage. The resin parts had more blow holes and flash than is usual today and the white metal parts needed much more fettling than I would normally expect.

Conclusion Despite the misgivings over the quality of the castings the pictures however show that a fine result can be achieved with patience. The only aspect of the "finished" model I am not happy with is the "windscreens" The white metal frames are unconvincing and the acetate was rather thick. I think I will be able to replace these with some parts created from scrap photo etch sprue.

Support us ordering our notes in PDF > Here |

||||||