|

|||||||||||||||||||||||||||||||||||

|

Motorcycles |

|

||||||||||||||||||||||||||||||||||

|

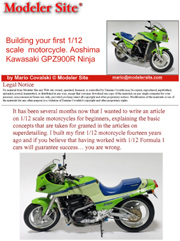

Building your first 1/12 scale motorcycle. Aoshima Kawasaki GPZ900R Ninja |

|||||||||||||||||||||||||||||||||||

|

by Mario Covalski © Modeler Site |

|||||||||||||||||||||||||||||||||||

|

Legal Notice No material from Modeler Site any Web site owned, operated, licensed, or controlled by Damian Covalski may be copied, reproduced, republished, uploaded, posted, transmitted, or distributed in any way, except that you may download one copy of the materials on any single computer for your personal, non-commercial home use only, provided you keep intact all copyright and other proprietary notices. Modification of the materials or use of the materials for any other purpose is a violation of Damian Covalski's copyright and other proprietary rights. Read More here > Legal notice It has been several months now that I wanted to write an article on 1/12 scale motorcycles for beginners, explaining the basic concepts that are taken for granted in the articles on superdetailing. I built my first 1/12 motorcycle fourteen years ago and if you believe that having worked with 1/12 Formula 1 cars will guarantee success… you are wrong. Though the scale is the same as a whole, motorcycle parts are much smaller, their design engineering is different and the kit manufacturers' philosophy is different too. Thus, the solutions to the specific problems that these models present need to be adapted, since they are very different from those presented by cars. And if you are thinking of other scales, it is more or less the same, since the parts have different design engineering. Maybe it is easier to build a 1/6 than a 1/12 scale motorcycle, exception made of course, with the difficulties that handling and painting bigger parts bring about. The selected kit

Aoshima has been producing motorcycle kits -and injecting them in molds bought from other manufacturers, such as Imai and Bandai- for almost twenty-five years, i.e. more than Tamiya. However, I came across the brand not more than 7 or 8 years ago. Obviously, they have concentrated in the domestic market.

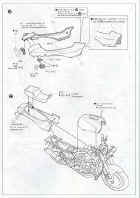

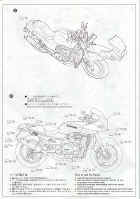

Building the model When I built my last kit in 1988, the techniques and materials I used and my own abilities were so different that I found myself as a beginner with his first kit. This was all right since I would be able to give a fresh view of the common problems and an experienced solution. This note is offered in PDF format to be read or printed using Acrobat reader, contact our webmaster > Here Includes more than 70 pics, here we show only the text pages.

Esta Nota es ofrecida en formato PDF, el cual puede ser leído o impreso usando el Acrobat reader, contacte a nuestro webmaster > Aquí Incluye más de 70 imágenes, aquí solo mostramos las paginas de texto.

Big size photos are only available in our PDF format. Support us ordering our notes in PDF > Here |

|||||||||||||||||||||||||||||||||||